How does Demargo (Shanghai) Energy Saving Technology Co., Ltd.'s Explosion-Proof Refrigerated Air Dryer meet the needs of an explosion-proof environment?

In high-risk industries such as petroleum, chemical industry, and natural gas, the safety and reliability of compressed air systems are crucial. The working environments of these industries usually contain flammable and explosive gases or dust, so it puts extremely high requirements on the explosion-proof performance of the equipment. As a leader in compressed air purification, Demargo (Shanghai) Energy Saving Technology Co., Ltd., launched the Explosion-Proof Refrigerated Air Dryer, with its advanced technology and excellent design, has become an ideal choice for explosion-proof environments.

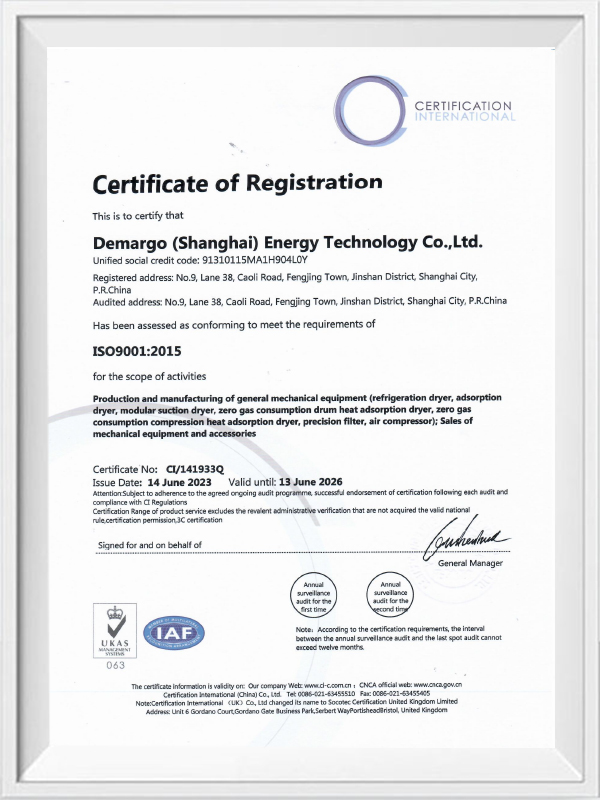

1. Strictly comply with explosion-proof standards and certification

Demargo's Explosion-Proof Refrigerated Air Dryer is designed and manufactured strictly in accordance with international and domestic explosion-proof standards, including ATEX, IECEx and China's explosion-proof certification (such as Ex d, Ex e, etc.). In addition, the equipment has passed ISO9001 quality system certification and QS certification to ensure its safety and reliability in explosion-proof environments. These certifications are not only a guarantee of equipment quality, but also a source of user confidence.

2. Explosion-proof materials and structural design

The equipment uses explosion-proof shells and special materials, which can effectively prevent sparks from occurring in internal electrical components or mechanical components, thereby avoiding explosions. Key components (such as compressors, condensers, etc.) are all explosively protected to ensure safe operation in a flammable and explosive environment. This design not only improves the safety of the equipment, but also extends its service life.

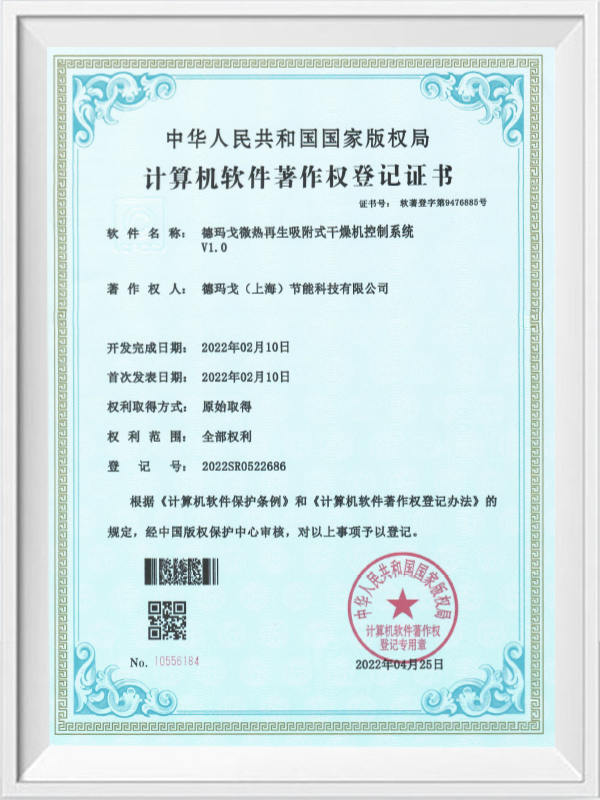

3. High efficiency cooling and intelligent temperature control

In explosion-proof environments, temperature control is one of the key factors in ensuring safety. Demargo's Explosion-Proof Refrigerated Air Dryer uses an efficient cooling system that can reduce the temperature of compressed air to a safe range (dew point temperature can reach -23℃) to avoid safety hazards caused by high temperatures. At the same time, the equipment is equipped with an intelligent temperature control system to monitor and adjust the operating temperature in real time to ensure the stability and safety of the equipment in an explosion-proof environment.

4. Sparkless electrical components

The electrical components inside the equipment (such as motors, controllers, etc.) are explosion-proof design to ensure that there is no spark or high temperature during operation. This feature is particularly important in high-risk industries such as petroleum and chemical industry. It can effectively avoid explosion accidents caused by electrical failures and provide users with additional safety guarantees.

5. Adapt to various hazardous environments

Demargo's Explosion-Proof Refrigerated Air Dryer is able to adapt to a variety of hazardous environments including Class I (gas), Class II (dust environment), and Class III (fiber environment). The equipment can be customized according to user needs to meet the requirements of different explosion-proof levels (such as Zone 1, Zone 2, etc.). This flexibility enables it to be widely used in multiple fields such as oil extraction, chemical production, and natural gas treatment.

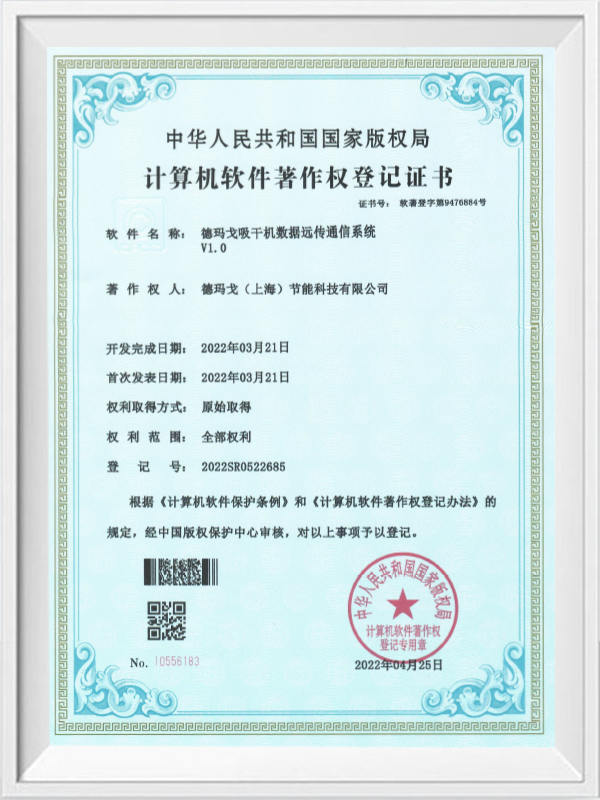

6. Intelligent monitoring and alarm system

The equipment is equipped with an intelligent monitoring system, which can detect operating status (such as temperature, pressure, humidity, etc.) in real time, and automatically alarm or shut down in abnormal situations to prevent accidents. This feature is particularly important in explosion-proof environments and can provide users with additional security while reducing the risk of equipment failure.

7. Wide application fields

Demargo's Explosion-Proof Refrigerated Air Dryer has been successfully applied to high-risk industries such as petroleum, chemical, natural gas, and pharmaceuticals, and has played an important role in many key projects at home and abroad. For example, during oil extraction and refining, equipment can safely and efficiently handle compressed air, ensuring the stability and safety of the production environment. In addition, the equipment is also exported to Brazil, Australia, Iran, India and other countries and regions, winning wide recognition.

8. Energy-saving and environmentally friendly characteristics

While meeting explosion-proof requirements, Demargo's Explosion-Proof Refrigerated Air Dryer also focuses on energy conservation and environmental protection. The equipment adopts high-efficiency and energy-saving technology, which can significantly reduce energy consumption and meet environmental protection requirements. For enterprises that focus on energy conservation and environmental protection (such as the chemical industry and the power industry), this feature not only improves safety, but also reduces operating costs.

9. Perfect after-sales service

Demargo provides comprehensive pre-sales and after-sales services, including equipment selection, installation guidance, maintenance, etc., to ensure the long-term and stable operation of the equipment in an explosion-proof environment. For high-risk industries, this service can help users minimize the risk of equipment failure and improve production efficiency.