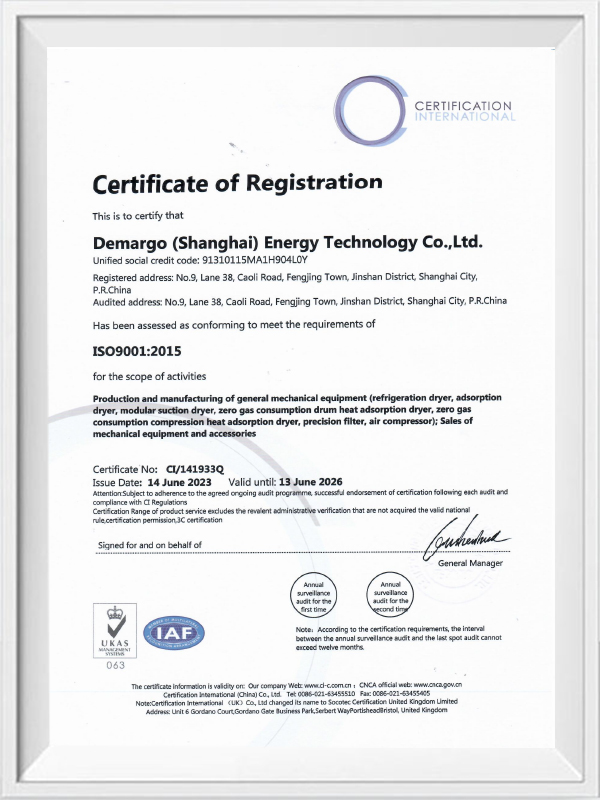

Demargo (Shanghai) Energy Saving Technology Co., Ltd. actively participates in and promotes the development of the compressed air industry. It specializes in manufacturing and producing compressed air purification equipment. So far, it has passed a number of product patents, QS certification, and ISO9001 quality system certification. It has obtained national high-tech and specialized enterprises, providing users with high-quality products and the most complete pre-sales and after-sales services.

Demargo (Shanghai) Energy Saving Technology Co., Ltd. is

China Wholesale Air Compressor Dryers | Refrigerated & Adsorption Dryers with Filters for Clean, Dry Compressed Air Manufacturers and

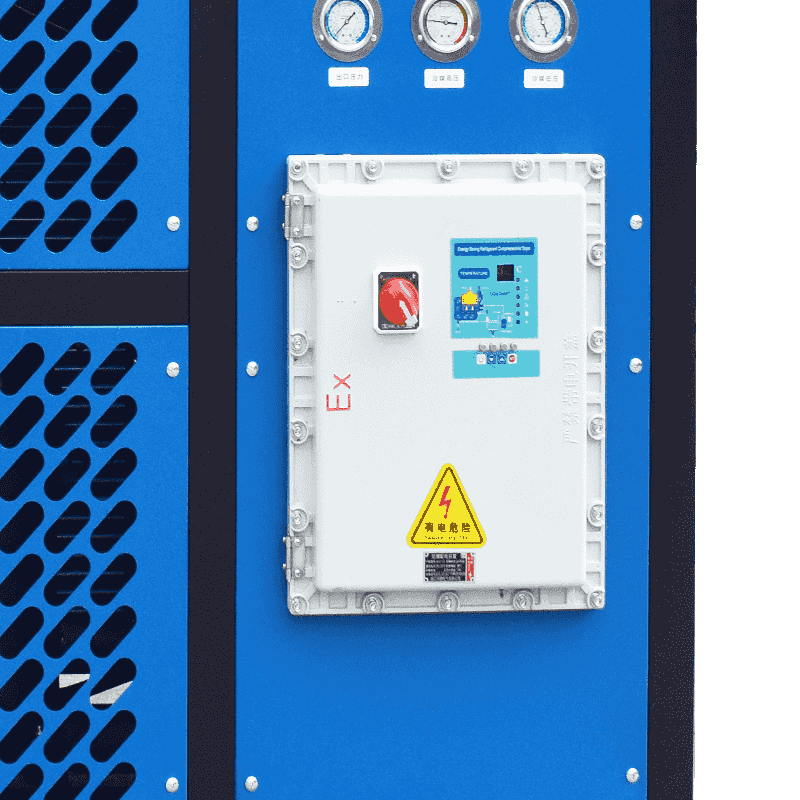

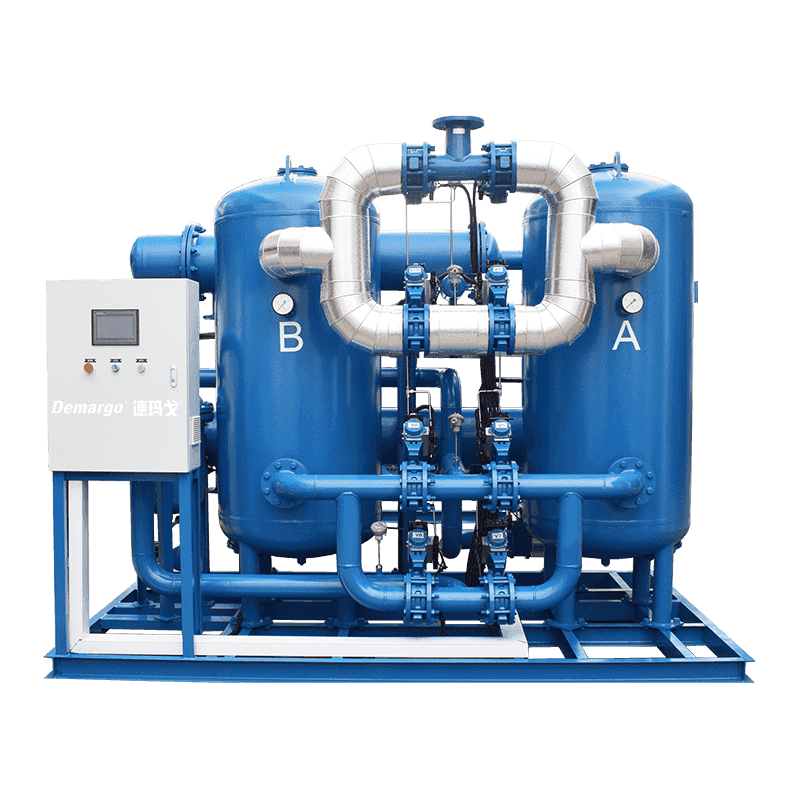

Air Compressor Dryers | Refrigerated & Adsorption Dryers with Filters for Clean, Dry Compressed Air Suppliers. It's products include refrigerated dryers, adsorption dryers, combined dryers, compression heat regeneration adsorption dryers and filters, zero air consumption blast heat dryers, self-cleaning air filters, compressed air pre-cooling units, low-temperature and high-pressure nitrogen pre-cooling units, industrial chillers, oil-water separators, high-efficiency oil removers, aftercoolers and other specifications. According to user needs, it can provide compressed air purification equipment with various types and characteristics such as air cooling, water cooling, standard, fluorine-free, high temperature, instrumentation, single-chip microcomputer, programmable, industrial computer, frequency conversion control, high pressure, explosion-proof, etc. Product dew point range. -23℃~-70℃, processing capacity: 1~500Nm3/min, export oil content: 10PPM~0.003PPM. Export dust particle size: 3um~0.01 um.

Demargo (Shanghai) Energy Saving Technology Co., Ltd. has strong product research, design and development capabilities. On the basis of digesting and absorbing advanced technologies at home and abroad, combined with the actual working conditions in China, the successfully developed Demargo brand air purification equipment is the best suction filtration and post-processing purification equipment for various oil-free and oil-free air compressors. The products are widely used in power, shipbuilding, aerospace, electronics, metallurgy, machinery, automobile manufacturing, petroleum, chemical industry, textile, chemical fiber, light industry, papermaking, rubber, instrumentation, food, air separation, cigarettes, medicine, biology, daily chemicals, and other industries. They are sold well in more than 30 provinces and cities across the country and play an active role in key national projects. The products have been exported to Brazil, Australia, Iran, India, Sudan, Indonesia, Vietnam, Saudi Arabia and other Southeast Asia, the Middle East and Central Asia, and Africa.

The company takes "sincere dedication and pursuit of excellence" as its corporate spirit, and achieves the goal of developing the business through technology, quality and service with advanced product design, comprehensive quality assurance and a fast pre-sales and after-sales service network. We offer

Air Compressor Dryers | Refrigerated & Adsorption Dryers with Filters for Clean, Dry Compressed Air for sale.